Welcome to our website!

DLP LED light source projector device applications

Source : This web site

Published : 2012/6/19

DLP LED light source projector device applications

DLP projector after nearly 20 years of development in recent years gradually by the severe impact of the LCD products, in response to changes in market conditions, a large-scale promotion and application of LED light source of DLP projectors in the last three years.

As we all know, most of the traditional DLP projector criticized the use of UHP light source, the average life expectancy of 6000 hours resulted in the user's costs are still lower, while the LED light source are 10 times the service life of UHP good solution this problem. But the LED light source perfect? ??In use and pay attention to what?

, Brightness, and the choice of the color gamut

LED light source, they have already attained in the traditional outdoor LED display K-class lumens DLP applications generally stay within the range of 600-800 lumens (bright operating mode), so the use of the environment ambient light to do more strictly controlled customers to minimize the sensitivity of the brightness of the LED light source.

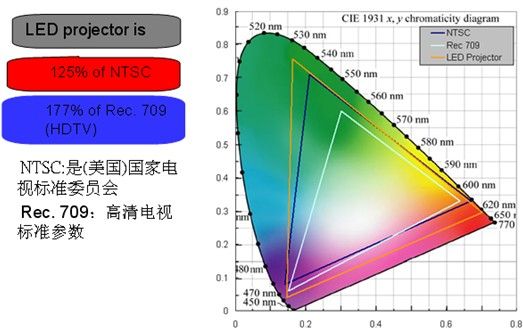

Due to the wide color gamut of the LED light source characteristics (see Figure 1), we have the opportunity to more complex environment. If the ambient light is usually cold white light or incandescent lamp, it is recommended that the color temperature adjustment range 7500-9300K, make eyes feel brighter, more vibrant colors.

Second, heat

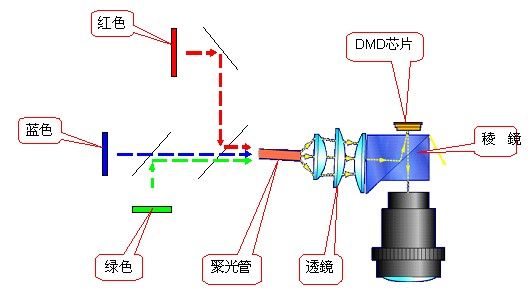

LED light source spectral characteristics, resulting in the case of equal brightness, the light part of the heat generated is higher than the UHP (see Figure 2). Therefore, the thermal design requirements for the entire projection display unit and the control of the ambient temperature to request more. Mainstream heat is air-cooled and water-cooled two. It should be said that the advantages and disadvantages. More traditional air-cooled, mature, water-cooled cooling efficiency slightly higher than the air-cooled, but the design more difficult, long-term reliability to be tested.

Third, maintenance

UHP light source due to the shorter life span, the brightness decreases rapidly, leading to put into use, a higher frequency of periodic debugging, to brightness, color uniformity is maintained at a certain level. The high life of the LED light source, low-attenuation characteristics of a good improvement in this situation, because there is no color wheel, also do not consider the impact of long-term operation of dust-ray machine output color (see Figure 3). This significant savings in maintenance manpower expenditures.

Fourth, the use of cost

The life of the LED light source to 60000h, and there is no color wheel, so in theory the device

Within the normal life cycle need to consider the expenditure of supplies,

To sum up, the LED light source projector in effect, the maintenance costs compared to UHP forward a big step, a breakthrough as soon as possible, as long as the light source brightness can be predicted within a certain time will dominate the entire high-end large screen splicing market

English

English

»

»